HVAC Services

Get Professional Repairs From The Area's Trusted HVAC Technicians. Ask About Our Services! We Offer Professional Heating & Cooling System Repairs And Guarantee Long-Lasting Results.

Got Question? Call us: (850) 678-2665Financing

Ductwork 101: Optimizing Airflow In Your Space

Learn how to optimize the airflow in your space with "Ductwork 101: Optimizing Airflow In Your Space." Discover practical tips and insights for improved comfort and energy savings.

In “Ductwork 101: Optimizing Airflow In Your Space,” you will discover practical tips and insights on how to maximize the efficiency of your heating and cooling system through effective ductwork. With the help of Tempacure Heating and Air Conditioning, a trusted company in Niceville, FL, you can learn how to ensure ideal airflow throughout your space, resulting in improved comfort and energy savings. Whether you are a homeowner or a business owner, understanding the basics of ductwork optimization is essential for creating a pleasant and cost-effective indoor environment. So, let’s dive into the world of ductwork and unlock the secrets to achieving optimal airflow in your space!

Understanding Ductwork

What is ductwork?

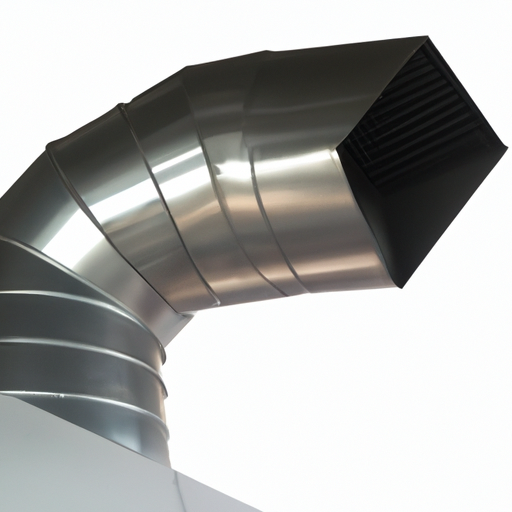

Ductwork is a crucial component of any heating, ventilation, and air conditioning (HVAC) system. It consists of a series of channels or passages through which air is transported to and from various parts of a building. Ductwork plays a vital role in maintaining comfortable indoor temperatures and ensuring proper airflow throughout the space.

Components of ductwork

Ductwork is comprised of several essential components. The main components include:

-

Supply ducts: These ducts carry conditioned air from the HVAC system to different rooms or zones in a building.

-

Return ducts: Return ducts bring back the air from the rooms to the HVAC system for reconditioning.

-

Registers and grilles: These are the visible components of the ductwork system, responsible for delivering or extracting air in each room.

-

Dampers: Dampers are adjustable plates within the ducts that control and regulate the airflow to specific areas. They are essential for maintaining the balance of airflow throughout the system.

Types of ductwork materials

Ductwork can be manufactured from various materials, each with its own advantages and considerations. The most commonly used materials for ductwork include:

-

Sheet metal: Sheet metal ductwork is durable, fire-resistant, and can be custom-fabricated to fit any space. It is often used in commercial buildings or where aesthetics are not a primary concern.

-

Flexible ducts: Made from a combination of plastic and metal wire helix, flexible ducts are easy to install and navigate around obstacles. They are commonly used in residential settings, especially when retrofitting or working in tight spaces.

-

Fiberglass duct boards: These are pre-insulated duct panels made from fiberglass and covered with a moisture-resistant facing. Fiberglass duct boards are lightweight, provide good thermal insulation, and are suitable for limited space applications.

-

Fiberglass lined ducts: Similar to fiberglass duct boards, fiberglass lined ducts have a layer of fiberglass insulation lining the inside. They provide both thermal insulation and sound attenuation properties.

-

Fabric ducts: Fabric ducts are made from permeable fabric materials and are ideal for open-ceiling designs or spaces where aesthetics are a priority. They offer a more even distribution of air and can be easily washed and maintained.

Understanding the different types of ductwork materials will help you choose the most suitable option for your specific needs and requirements.

Importance of Optimizing Airflow

Why is airflow important?

Proper airflow is essential for the optimal functioning and efficiency of your HVAC system. Without adequate airflow, your system may struggle to maintain consistent temperatures, resulting in discomfort and increased energy consumption. Airflow is necessary to distribute conditioned air evenly throughout the space, ensuring comfort in all areas.

Benefits of optimized airflow

Optimizing airflow in your ductwork system offers several benefits, including:

-

Enhanced comfort: Proper airflow ensures that conditioned air reaches every corner of your space, providing uniform temperatures and a comfortable environment for occupants.

-

Energy efficiency: When airflow is optimized, the HVAC system can deliver conditioned air more efficiently, reducing energy consumption and lowering utility bills.

-

Better indoor air quality: Proper airflow helps to remove pollutants, dust, and allergens from the air, ensuring a healthier indoor environment.

-

Extended HVAC system lifespan: When airflow is optimized and balanced, it reduces strain on the system, leading to fewer breakdowns and extending the life of your HVAC equipment.

Issues caused by poor airflow

Poor airflow can lead to various issues, such as:

-

Hot and cold spots: Inadequate airflow can result in certain areas of a room being too hot or too cold, creating discomfort for occupants.

-

Uneven temperature distribution: Insufficient airflow may cause temperature imbalances between different areas of the building, leading to inconsistencies in heating or cooling.

-

Reduced energy efficiency: When airflow is restricted or unbalanced, the HVAC system must work harder to compensate, resulting in increased energy consumption and higher utility bills.

-

Increased wear and tear: Poor airflow can cause excessive strain on the HVAC system, leading to increased wear and tear on components and potential system failures.

By understanding the importance of optimizing airflow and the consequences of poor airflow, you can take proactive steps to ensure efficient and balanced airflow throughout your ductwork system.

Calculating Airflow Requirements

Determining proper airflow

Correctly calculating the airflow requirements for your ductwork system is crucial for achieving optimal performance. The airflow requirements depend on various factors, including:

-

Size and layout of the space: Larger rooms or buildings require higher airflow rates to maintain comfortable temperatures.

-

Occupancy level: Areas with many occupants, such as offices or classrooms, will require increased airflow to ensure proper ventilation and comfort.

-

Heat gain and loss: The amount of heat gained or lost through walls, windows, and insulation affects the airflow needed to maintain desired temperatures.

-

Equipment and appliances: Heat-producing equipment or appliances in a space will require additional airflow to dissipate the heat effectively.

It is essential to work with HVAC professionals who can accurately assess the specific requirements of your space and calculate the ideal airflow rates for your ductwork system.

Factors affecting airflow requirements

Several factors can impact the airflow requirements for a ductwork system, including:

-

Air distribution method: Different air distribution methods, such as overhead diffusers or underfloor outlets, may require varying airflow rates to achieve the desired results.

-

Duct length and size: Longer duct runs and smaller duct sizes may result in higher friction losses and require increased airflow rates to compensate.

-

Duct material and design: The material and design of the ductwork can impact airflow resistance and, consequently, the required airflow rates.

-

Air velocity: The velocity at which air is delivered or extracted can affect the airflow requirements. Higher air velocities may necessitate greater airflow rates for proper distribution.

By considering these factors and working with HVAC professionals, you can ensure that your ductwork system is designed and sized to meet the specific airflow needs of your space.

Designing Efficient Ductwork System

Sizing the ducts

Properly sizing the ducts is crucial to ensure optimal airflow, comfort, and energy efficiency. Undersized ductwork can restrict airflow, leading to inadequate heating or cooling, while oversized ducts can cause air turbulence and increased energy consumption. By considering factors such as room size, layout, and the airflow requirements discussed earlier, HVAC professionals can determine the appropriate duct size for each space.

Choosing the right layout

The layout of your ductwork system is another critical aspect of promoting efficient airflow. The layout should ensure that conditioned air is evenly distributed throughout the space, avoiding hot or cold spots. A well-designed ductwork layout minimizes the length of duct runs, utilizes smooth bends instead of sharp turns, and avoids obstructions that could restrict airflow.

Minimizing air leaks

Air leaks in the ductwork can significantly impact airflow and reduce the overall efficiency of your HVAC system. Air leaks can occur at connections, joints, or poorly sealed ducts, allowing conditioned air to escape into unconditioned spaces, such as attics or crawl spaces. By properly sealing all connections and joints, using appropriate sealing materials, and performing regular inspections, you can minimize air leaks and optimize airflow.

Selecting proper insulation

Proper insulation of the ductwork is essential for maintaining the desired temperatures and preventing heat gain or loss during air transport. Insulation helps to minimize temperature fluctuations, reduce energy loss, and prevent condensation. Fiberglass insulation or other appropriate insulation materials should be applied to the exterior of the ducts to improve energy efficiency and ensure optimal performance.

Designing an efficient ductwork system involves careful consideration of duct sizing, layout, air leakage prevention, and insulation. By working with experienced HVAC professionals, you can ensure a well-designed system that promotes efficient airflow and maximizes comfort.

Types of Duct Systems

Single-zone versus multi-zone systems

Duct systems can be classified into single-zone or multi-zone systems based on the number of areas the system serves. In a single-zone system, a single thermostat controls the heating and cooling for the entire space. This type of system is suitable for smaller buildings or spaces with consistent heating or cooling needs.

On the other hand, multi-zone systems divide the space into multiple areas or zones with separate thermostats. Each zone has its own dampers and controls, allowing for independent temperature regulation. Multi-zone systems are more suitable for larger buildings or spaces with varying heating or cooling requirements in different areas.

Flex ducts versus rigid ducts

Flex ducts and rigid ducts are two common types of duct systems used in residential and commercial applications.

Flex ducts, as the name implies, are flexible and bendable. They consist of a flexible inner liner surrounded by insulation and an outer vapor barrier. Flex ducts are lightweight, easy to install, and can be routed around obstacles more easily than rigid ducts. They are commonly used in residential settings or areas with limited space for ductwork installations.

Rigid ducts, on the other hand, are stiff and cannot be bent. They are typically made of sheet metal, fiberglass, or other rigid materials. Rigid ducts offer better airflow efficiency and are often used in commercial buildings or where aesthetics are a priority.

Round ducts versus rectangular ducts

Both round ducts and rectangular ducts are used in ductwork systems, and each has its own advantages and considerations.

Round ducts are well-suited for balancing airflow and reducing pressure drop, which can optimize the efficiency of the HVAC system. They are also less prone to air leakage than rectangular ducts since they don’t have corners. Round ducts are commonly used in residential HVAC systems and are often less expensive to install.

Rectangular ducts, on the other hand, are more space-efficient and easier to install in confined areas. They can be custom-fabricated to fit specific spaces and are often used in commercial buildings or areas with unique architectural requirements.

Choosing the appropriate type of duct system depends on various factors, including the specific application, available space, aesthetics, and budget considerations.

Common Ductwork Problems

Restricted airflow

Restricted airflow is a common issue that can occur in ductwork systems. It can be caused by several factors, such as undersized ducts, improper duct layout, blocked vents or registers, or excessive dust and debris buildup. Restricted airflow can lead to reduced comfort, temperature imbalances, and increased energy consumption. regular inspection and maintenance, including cleaning and removing obstructions, can help alleviate restricted airflow and ensure optimal system performance.

Air leaks and energy loss

Air leaks in the ductwork can result in significant energy loss and reduced system efficiency. Leaks can occur at joints, connections, or poorly sealed ducts, allowing conditioned air to escape and unconditioned air to infiltrate the system. This not only wastes energy but also compromises indoor comfort and air quality. Properly sealing ductwork, including connections and joints, is essential to prevent air leaks and minimize energy loss.

Unbalanced airflow

Unbalanced airflow in a ductwork system refers to uneven distribution of air between different areas or zones. This can cause hot or cold spots and discomfort for occupants. Unbalanced airflow can be caused by factors such as improper duct sizing, blocked vents, or malfunctioning dampers. HVAC professionals can identify and rectify the root causes of unbalanced airflow through proper ductwork design, sizing, and regular maintenance.

Addressing common ductwork problems promptly through regular maintenance, cleaning, and inspection can help ensure optimal airflow, energy efficiency, and comfort in your space.

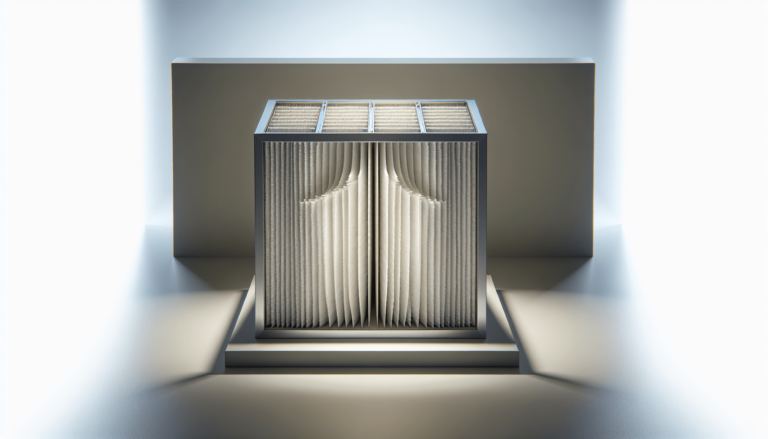

Ductwork Maintenance

Regular cleaning and inspection

Regular cleaning and inspection of the ductwork are essential for maintaining proper airflow, indoor air quality, and system efficiency. Over time, ducts can accumulate dust, dirt, allergens, and other pollutants. These contaminants can hinder airflow, affect air quality, and even contribute to health issues. Professional duct cleaning services use specialized equipment to remove debris and ensure a clean and healthy ductwork system.

Regular inspections are also crucial. HVAC professionals can identify and rectify issues such as air leaks, damaged or disconnected ducts, or any other potential problems that may affect airflow or system performance.

Sealing ductwork

Properly sealing ductwork is necessary to prevent air leaks, improve energy efficiency, and optimize airflow. Air leaks can occur at connections, joints, or poorly sealed ducts, leading to inefficient system operation and increased energy consumption. By using sealants and appropriate sealing materials, HVAC professionals can effectively seal the ductwork and minimize air leaks.

Replacing damaged ducts

Ducts can become damaged over time due to factors such as age, wear and tear, or improper installation. Damaged ducts can result in restricted airflow, air leakage, and compromised system performance. HVAC professionals can assess the condition of the ductwork and recommend appropriate repairs or replacements if needed. Replacing damaged ducts ensures the integrity of the system and promotes optimal airflow and efficiency.

By regularly maintaining, cleaning, inspecting, and sealing your ductwork system, you can enhance the performance, reliability, and longevity of your HVAC system.

Maximizing Airflow Efficiency

Using air deflectors and dampers

Air deflectors and dampers are valuable accessories that can help maximize airflow efficiency in your ductwork system. Air deflectors are installed on vents or registers to direct airflow in a specific direction or prevent it from being blocked by furniture or obstructions. Dampers, as mentioned earlier, are adjustable plates within the ducts that regulate airflow to specific areas. By using air deflectors and adjusting dampers, you can optimize the distribution of conditioned air and ensure balanced airflow throughout the space.

Utilizing zoning systems

Zoning systems divide a space into separate areas or zones and allow for independent temperature control and airflow regulation. By controlling airflow to specific areas based on occupancy, individual preferences, or heating and cooling requirements, zoning systems can maximize comfort and energy efficiency. Zoning controls can be installed in conjunction with motorized dampers to automatically adjust airflow to different zones, ensuring the right amount of conditioned air is delivered where it is needed most.

Adding booster fans

Booster fans are additional fans installed in the ductwork system to increase airflow to areas where it may be insufficient due to long duct runs or excessive resistance. Booster fans can help overcome air pressure imbalances and improve overall system performance. However, it is important to consult with HVAC professionals to ensure that the addition of booster fans is appropriate for your specific ductwork system and needs.

By utilizing air deflectors, dampers, zoning systems, or booster fans, you can maximize airflow efficiency, enhance comfort, and improve performance in your ductwork system.

Benefits of Professional Ductwork Services

Expertise in airflow optimization

HVAC professionals have the expertise and knowledge to optimize airflow in your ductwork system. They can accurately assess airflow requirements, duct sizing, layout, and insulation needs based on your specific space and HVAC system. Their expertise ensures that your ductwork system is designed and optimized for maximum efficiency, comfort, and energy savings.

Professional duct cleaning

Professional duct cleaning services can significantly improve indoor air quality by removing accumulated dust, dirt, allergens, and other contaminants from the ductwork. This helps to prevent or alleviate respiratory issues, reduce allergies, and create a healthier indoor environment. Certified professionals use specialized equipment and techniques to ensure thorough cleaning and remove even the most stubborn buildup.

Efficient ductwork installation and repair

Qualified HVAC professionals have the necessary skills and knowledge to install and repair ductwork systems efficiently. Proper installation is crucial for optimal performance and longevity of the system, while timely repairs can prevent further damage and maintain efficient airflow. By entrusting ductwork installation and repair to professionals, you can ensure that the job is done right the first time, saving time and money in the long run.

By utilizing professional ductwork services, you can benefit from their expertise in airflow optimization, ensure clean and healthy indoor air, and receive efficient installation and repair services.

Conclusion

Optimizing airflow in your ductwork system is essential for ensuring comfort, energy efficiency, and system performance. Understanding the components of ductwork, different materials, and the importance of airflow optimization will help you make informed decisions regarding your HVAC system. Calculating airflow requirements, designing an efficient ductwork system, and addressing common problems through maintenance and repairs will help maximize airflow efficiency in your space. By utilizing professional ductwork services, you can benefit from their expertise and ensure that your ductwork system is functioning optimally. Remember to regularly clean, inspect, and seal your ductwork to maintain efficient airflow and a healthy indoor environment.